Stories of Manufacturing #03

For everyone who loves music

~The Birth of MUS-ICAudio Device Development

ROHM Audio Devices

Thomas Edison invented the first gramophone (phonograph) in 1877. Since then, over the next 100 years, the world of audio has evolved through to analog signal media such as LP records and magnetic tapes (reel-to-reel and compact cassettes).

The following 40 years saw even more dramatic advancements. From the fusion of digital technology with video equipment centered on CDs popularized in the mid-80s to the spread of compressed audio files and emergence of high-resolution audio sources from the 2000s, the evolution and transformation of the music industry shows no signs of slowing down.

ROHM has been developing innovative ICs that meet the needs of the times for nearly 50 years, beginning in the '70s. Similarly, in the semiconductor industry, where integration and functionality have progressed dramatically in step with the audio industry, we have commercialized a succession of audio devices that take advantage of our strengths in analog technology.

Our current lineup includes audio amps, sound processors, and audio DACs/CODECs that have been adopted by a wide variety of commercial audio manufacturers.

Rich musicality that expresses the performer's world view

In recent years, we have been focusing on the development of high fidelity products for high-end audio equipment. The proliferation of high resolution audio sources has increased the demand for advanced technology that converts high definition digital audio data to analog without losing any of the original data. In 2018 we released the MUS-IC series, our premier lineup of audio ICs that focuses on unique audio quality design to pursue 'musicality' that cannot be measured by numerical performance.

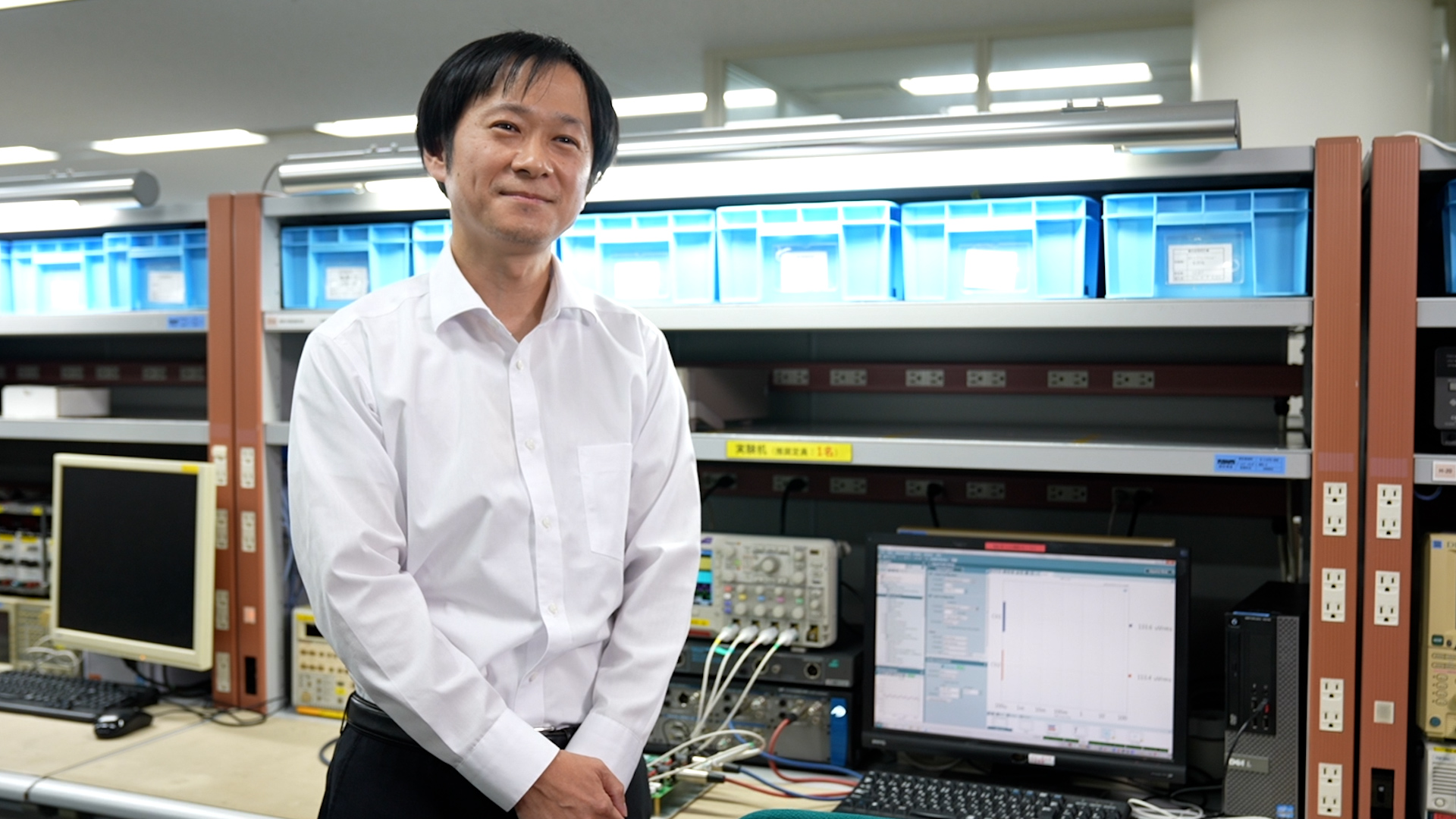

We asked the developer, Mr. Sato of the LSI Business Division, about his thoughts on the subject.

Key visual of the MUS-IC series. Shown here is the main hall of ROHM Theatre Kyoto, a space designed to resonate with profound orchestral sound.

2 LSI Business Division

I’ve been working in the Audio IC Development Department since joining the company.

I don’t have any background in music education, though I was in a pop band as a student.

The video at the top of the page shows the long process of trial and error that began when we asked the customer of an audio manufacturer to provide feedback on the direction of sound the MUS-IC series should take.

Sato:

‘One is natural resonance and realism, as if you were listening in a concert hall. The second is dynamic range (sense of scale) that properly expresses everything from extremely small sounds to large amplitudes. The third is the feeling of tension before the performance starts, as if you were there waiting (quietness). By achieving these 3, we hope to represent the world view of music created by the performers as much as possible.’

Electrical characteristics and sound quality represent two wheels on an axle

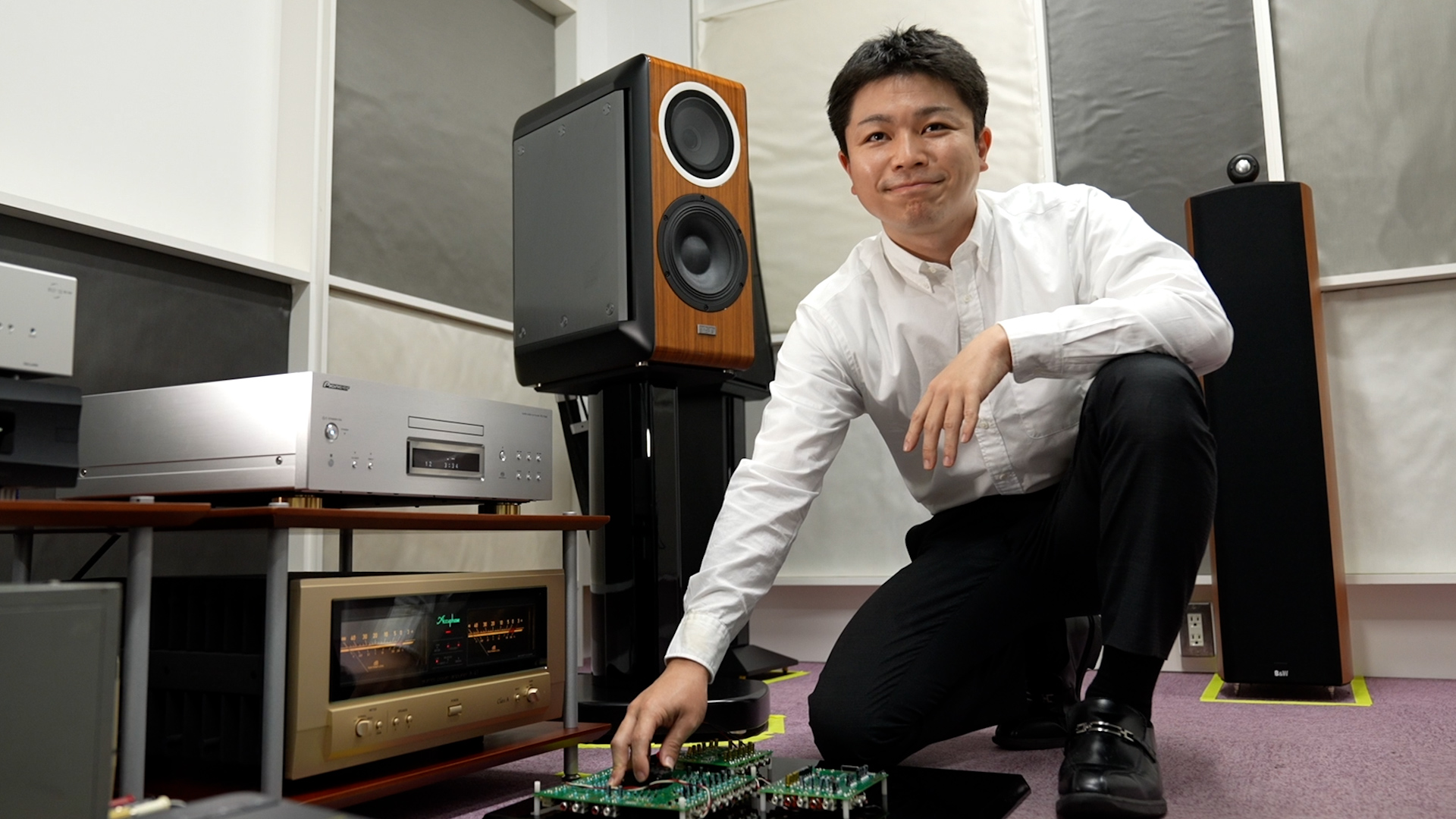

In 2020, the BD34301EKV 32bit audio DA converter IC, part of the MUS-IC series, was adopted in the latest SACD/CD player from Luxman Corporation.

What kind of sound was required of Luxman's highly acclaimed new flagship model D-10X?

Mr. Nagatsuma, Manager of the Development Department at Luxman, responded.

After working at a home appliance technology research institute of a major electronics manufacturer, my passion for audio products prompted my move to Luxman, where I was involved in the development of CD players and pre-main amplifiers.

Nagatsuma:

‘My first impression was that the sound quality was powerful but straightforward.

To put it more succinctly, the highs stand out and the lows are not overpowering, with nothing sticking out, leading to a natural feeling.’

Each high end audio equipment manufacturer has their own characteristics and preferences in sound quality, creating brand individuality.

When asked what kind of sound quality Luxman is pursuing, it appeared that there were some elements that overlapped with ROHM’s aforementioned goals for sound quality design.

Luxman’s ‘5 pillars’ of sound quality.

In study sessions these elements are usually talked about first.

Nagatsuma:

‘Actually, during the development of the D-10X, we had pretty much already decided which company to use for the D/A converter chip. It’s true that I was quite anxious. At that time, Mr. Sato told us that there was a new D/A converter chip and asked us to evaluate it, so we decided to give it a listen.’

▲

BD34301EKV

32bit audio D/A converter IC

mounted inside the D-10X

◀Luxman

D-10X SACD/CD Player

figure left:Luxman D-10X SACD/CD Player

figure right:BD34301EKV 32bit audio D/A converter IC mounted inside the D-10X

Nagatsuma:

‘After that, we had them make modifications as we identified the characteristics of the IC, and were able to finish the product in a natural way through mutual compromise.

Electrical characteristics and sound quality are like two wheels on an axle, so it’s not enough if one is better than the other. Both need to be better.’

Mr. Nagatsuma, who expressed his satisfaction, evaluates his communication with Mr. Sato as ‘having an ear that can talk about sound at the same level.’ The conversation proceeded smoothly since he was able to listen and evaluate sound quality in a way that was both objective and subjective, which tends to fall into the realm of personal preference. These words pleased Mr. Sato, who had spent a long time cultivating an ear that can discern the difference between minute sounds.

28 Parameters in a Vertically Integrated Production System

figure top:The standard song for listening is the live

version of ‘Hotel California’ by the Eagles.

The sound separation and localization were

deemed to be extremely good.

figure bottom:The laboratory in the Yokohama Technology

Center located in the front of the Shinkansen

Shin-Yokohama Stationprovides a different

look from the listening room.

Sato:

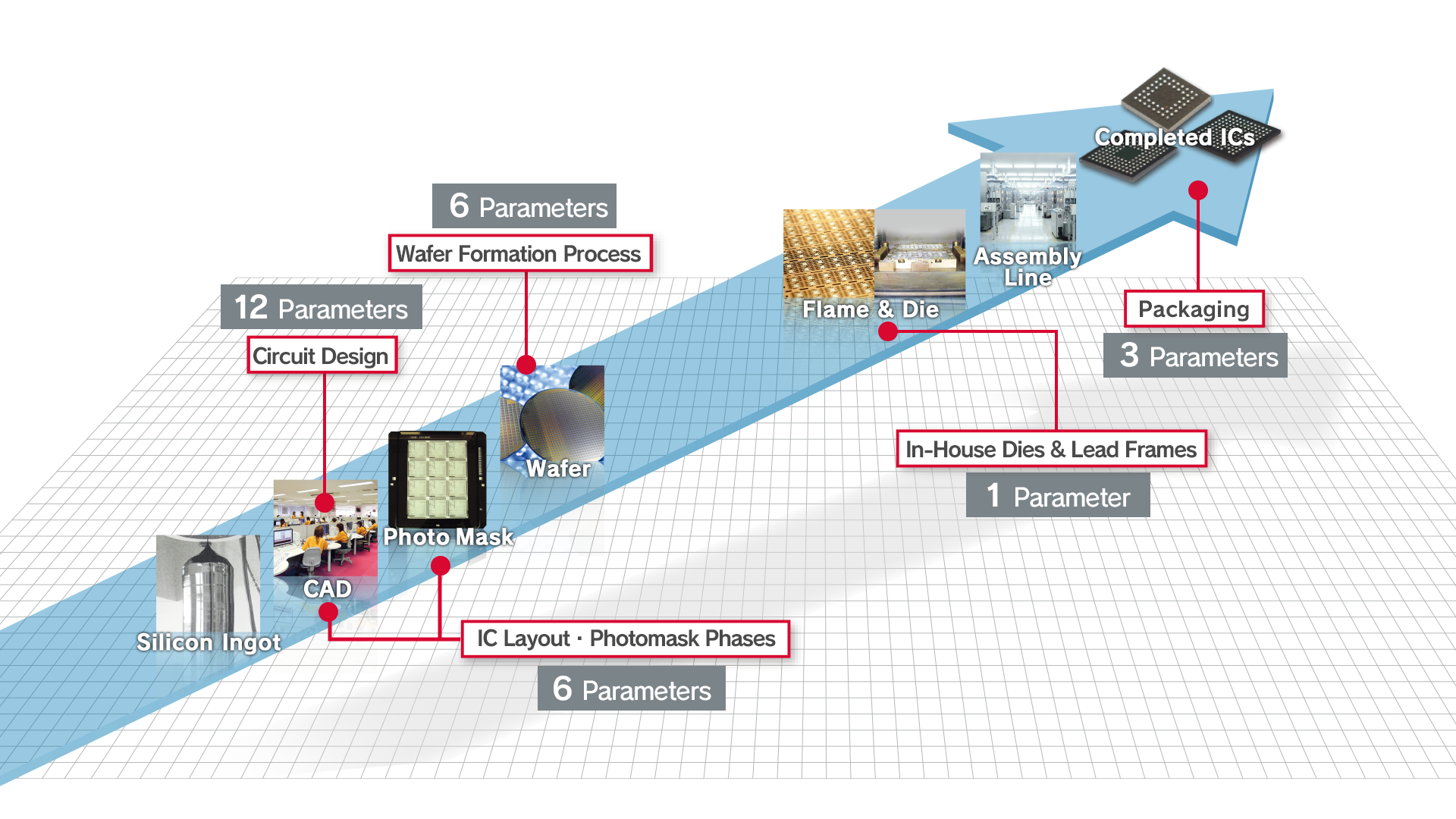

‘While listening to the sounds of our existing products, we compared the circuit design and manufacturing process to see how the sound would change depending on the characteristics and conditions.

As we continued with our efforts, we gradually came to understand the conditions that could influence sound quality. This is how we determined the 28 parameters that affect sound quality.'

ROHM’s advantage is a vertically integrated production system,

in which everything from ingot pulling to packaging is performed in-house.

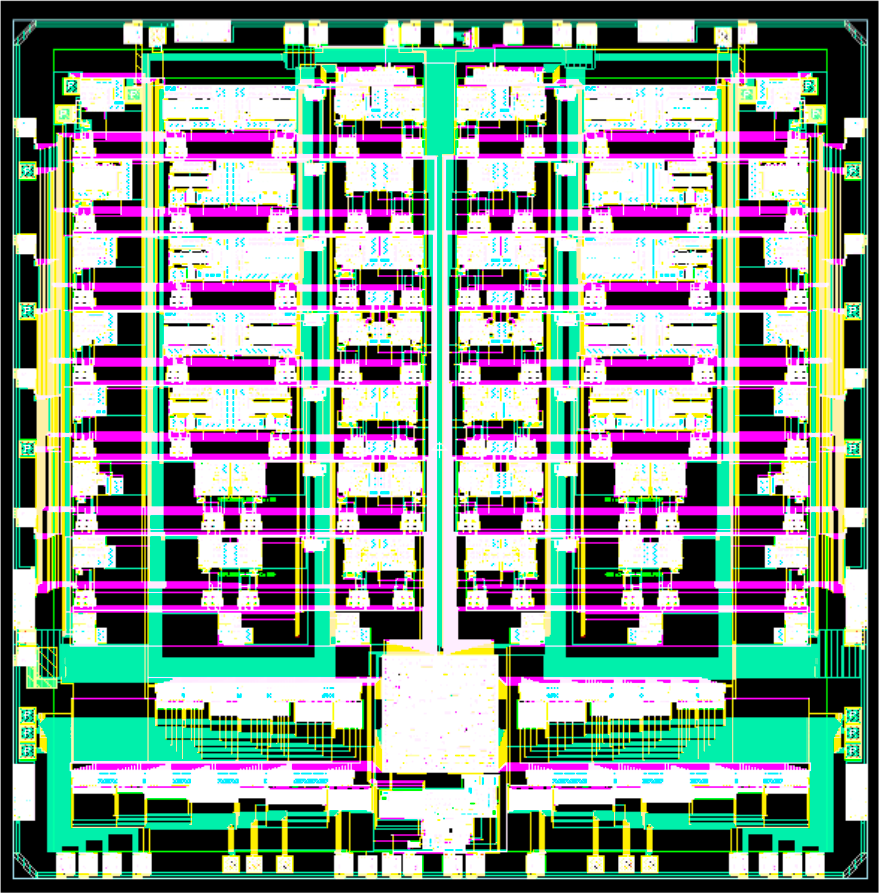

Development work requires the perseverance to constantly check sound quality in a dedicated listening room before incorporating it into the circuitry and packaging. The approach put into practice by Mr. Sato and his team shows the major features unique to ROHM. It requires a close relationship with our vertically integrated production system put in place since the company’s inception.Utilizing a vertically integrated manufacturing system allowed us to explore more parameters not only in circuit design but in all processes, from wafer fabrication to packaging.

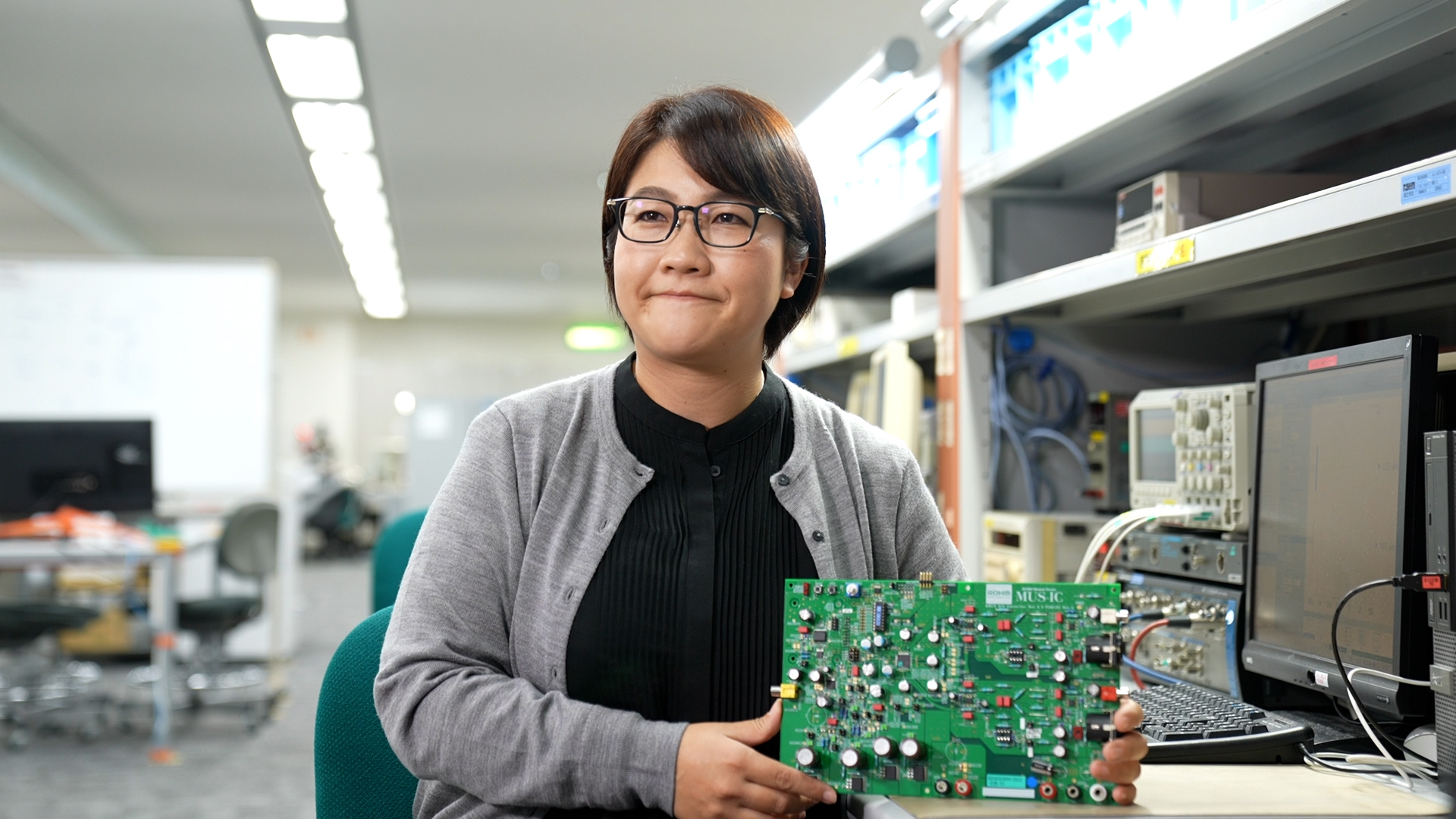

Test chip for investigating sound quality factors

We designed a test chip that incorporates points of concern while investigating existing products, etc. This was used to identify the 28 parameters.

Sato:

‘Thinking back, in the pursuit of sound, I asked members of the development team and people in the manufacturing department in charge of post-processing (after circuit design) for a lot of impossible things.’

Acknowledgment from the Manufacturing Dept.

Hamazawa:

‘We received a request to create test chips in various patterns, but it is not easy to change the conditions for mass production. So I thought he was a troublesome person.’

A view of the clean room from the observation area of ROHM’s main factory in Kyoto. Although the official name is VLSI Research Center, it is commonly referred to a ‘V Lab’.

Hamazawa, General Manager in charge of technology development, talks about those days.

After making several trips from the main factory in Kyoto to the Yokohama Technology Center where Mr. Sato works and actually listening to the difference in sound, he gradually changed his mind.

Hamazawa:

‘When I listened to the sound, I began to notice subtle differences. And I could feel his passion.’

This passion for creating sounds that spread to Mr. Hamazawa led him to conduct independent experiments and even create test chips even without being asked to do so. Mr. Hamazawa focused on the relationship between sound quality and chip cooling and even created a prototype. ’But it sounded a bit stiff, so we didn't end up adopting it,’ he says with a wry smile. However, the indescribable expression on his face can only be interpreted to mean ‘manufacturing spirit’ or ‘depth of craftsmanship’.

Sharing and passing on knowledge

‘The sound of the guitar strings is remarkably clear.’

‘But isn’t the localization narrower? Pay attention and listen!’

Although few words were spoken, it is important to share the points that should be heard.

ROHM’s ‘sound quality design’ was painstakingly developed over a long period of time under the leadership of Mr. Sato.

The entire development team in the audio division is currently utilizing this knowledge in product creation.

As Luxman’s Nagatsuma said, sharing the listening experience with others, which is highly dependent on individual senses, is a more difficult and ambiguous task than one might think.

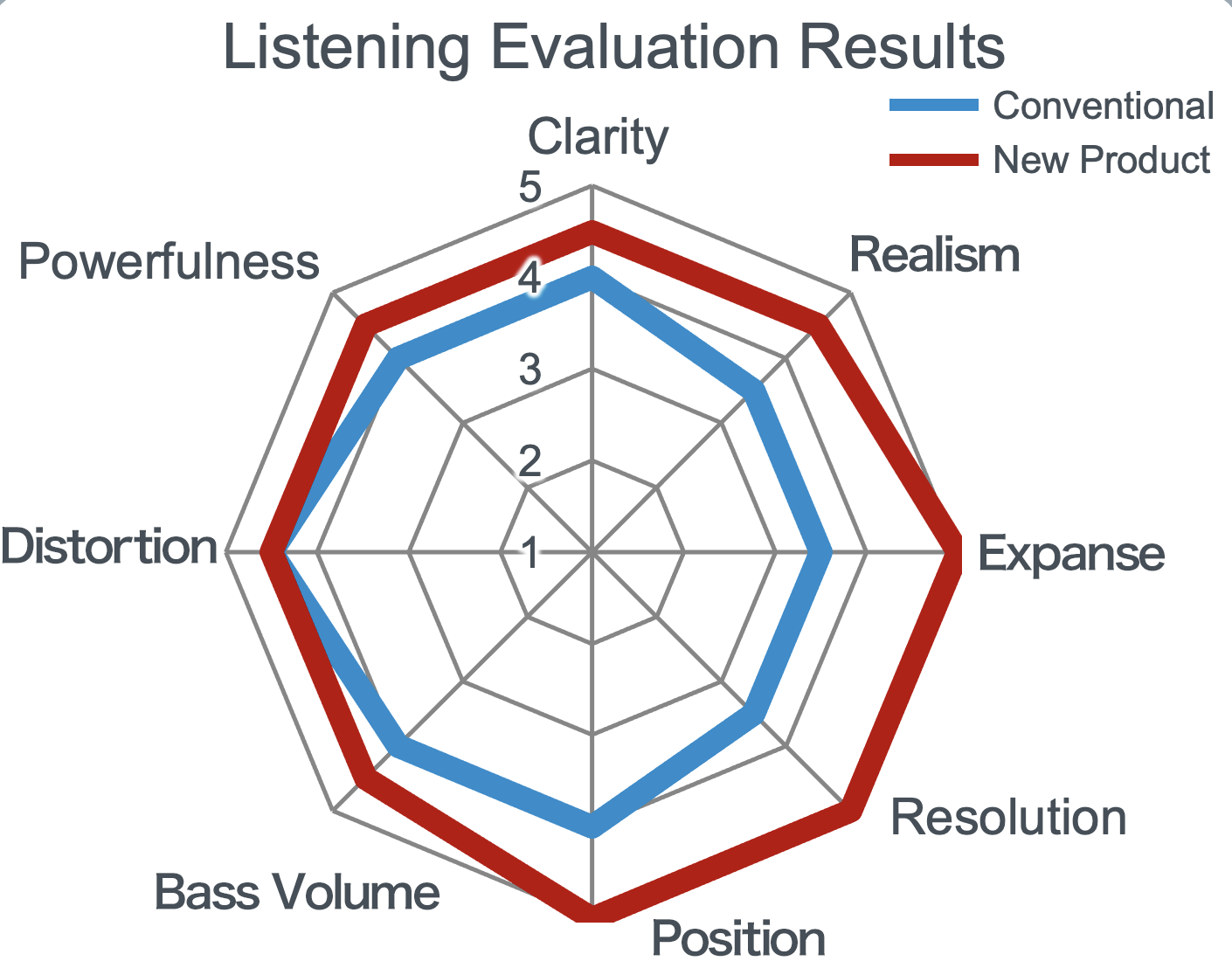

But by standardizing and utilizing special techniques such as sensory knowledge and skills, we can achieve growth as an organization that also plays an important part for the future of ‘monozukuri’ (manufacturing). The sound quality comparison chart below is used as one of these attempts

Sound Quality Comparison Chart

The chart graph consists of 8 items related to Clarity, Realism, Expanse, Resolution, Position, Bass Volume, Distortion, and Power.

This standardized example is used to develop engineers with a discerning ear.

Sato:

‘The engineers in the audio department are insatiable in their pursuit of the best sound. And I believe that all of the members have been able to share the sound quality they want to achieve through repeated listening sessions. It is incredibly reassuring to know that we’re on the same vector.’

Our commitment to sound is not only infused in our products,

but also in the evaluation boards we provide to customers.

It is a relentless challenge to see how far we can take something so sensory as listening by ear and put it into a circuit...

Musicians put their heart and soul into their music,

and we hope to approach LSI design with the same passion.

Just as a musician’s pursuit of music knows no end, so is the reproduction of high quality sound, says Sato.

In other words, as long as there is music in the world, the challenge will continue.

Related Link(s)

ROHM MUSICAL DEVICE MUS-IC https://micro.rohm.com/en/mus-ic/

Sato:

‘In short, what we are aiming for is ‘faithful sound reproduction’.

I believe that the ultimate purpose of audio equipment is to bring back the emotion that music creates in a realistic way anytime, anywhere, which can never come from a design based solely on electrical characteristics such as distortion and noise. I became aware of this fact long after I had been involved in audio IC development.’